Drilling to begin after Tihar festival, 4,000 metric tons of ore to be extracted daily

KATHMANDU: The country’s largest iron mine, discovered in Jhumlabang, located in ward 3 of Bhume Rural Municipality, Rukum Purba, has shown great potential for iron production. An investigation by the Department of Mines and Geology found that there are 20 crore metric tonnes of iron ore (raw material for iron) there. Preparations are underway to begin drilling work at the mine immediately after the Tihar festival.

According to the preliminary plan of the company that received the mining license, 4,000 metric tons of iron ore will be excavated daily once the mine is operational. At this rate, working 270 days a year, at least 1.08 million metric tons will be extracted. Excavating 4,000 metric tons of ore daily, the mine will last for 185 years. This could supply up to 40 percent of the domestic demand for iron.

The demand for iron-related materials in Nepal is 20,000 tons daily. Iron is the item imported the most after petroleum products in Nepal. According to the Department of Customs, iron worth Rs 107.79 billion was imported in the fiscal year 2024/25.

The Jhumlabang mine, which has the potential to lead the country towards import substitution, has now reached the stage of starting drilling. Only after drilling will the door to the mine operation open. Elevate Mines and Minerals, a company that obtained the license from the Department of Mines and Geology, is set to undertake this work. The company is preparing a work plan for mining excavation. The company is working to submit the work plan to the Department of Mines by the coming March, 2026, according to Kushal Nandan Pokharel, Senior Divisional Geologist at the Department. “The drilling work, however, will start immediately after the Tihar festival is over,” he says.

There are human settlements in the area where the mine was found. Although the locals initially said they would not allow drilling, after discussion, they have become positive about allowing the work to proceed after reaching some sort of agreement, says Dinesh Karmacharya, a director of Elevate Mines and Minerals. The team, including Karmacharya, returned from the mine site on July 7, 2025. Karmacharya says, “There is no situation to relocate the settlement immediately for the mine. Relocating the settlement would be the best option when the excavation begins.”

The Department of Mines generally issues licenses directly for the discovery and excavation of mines. However, in Jhumlabang, after discovering the mine itself and conducting the first phase of study, it issued a license for both excavation and production. Therefore, this is a special type of license. Senior Divisional Geologist Pokharel of the Department says, “We issued the license after only discovering the mine and completing one phase of study, by holding competition among private companies. Since the department itself conducted the study, the license was given under a special mineral category, rather than the regular process.”

Photo: Sujan Devkota

The department had sought technical and financial proposals to operate the mine. Some six companies submitted proposals. The financial proposal of only the company that succeeded in scoring 50 percent in the technical proposal was opened. Elevate Mines and Minerals, which proposed Rs 435.1 million, was awarded the license.

According to Karmacharya, Elevate has submitted a proposal to excavate 4,000 tons daily now but will submit a new proposal after further study of the mine. “We will only get permission for excavation after that is approved. Even after that, we must conduct an EIA (Environmental Impact Assessment),” he says. “After the EIA is complete, we must acquire the forest’s right of use. Most of the excavation site falls within the forest area. It will take us at least three years to reach the excavation phase of the mine.”

If the current plan is implemented, the company will operate the mine in an area of 7.5 square kilometers. The estimated cost for this is expected to be more than Rs 100 billion. The projection is that up to 12,000 metric tons of iron ore will be excavated daily once the mine is fully operational.

Iron mine found while looking for copper

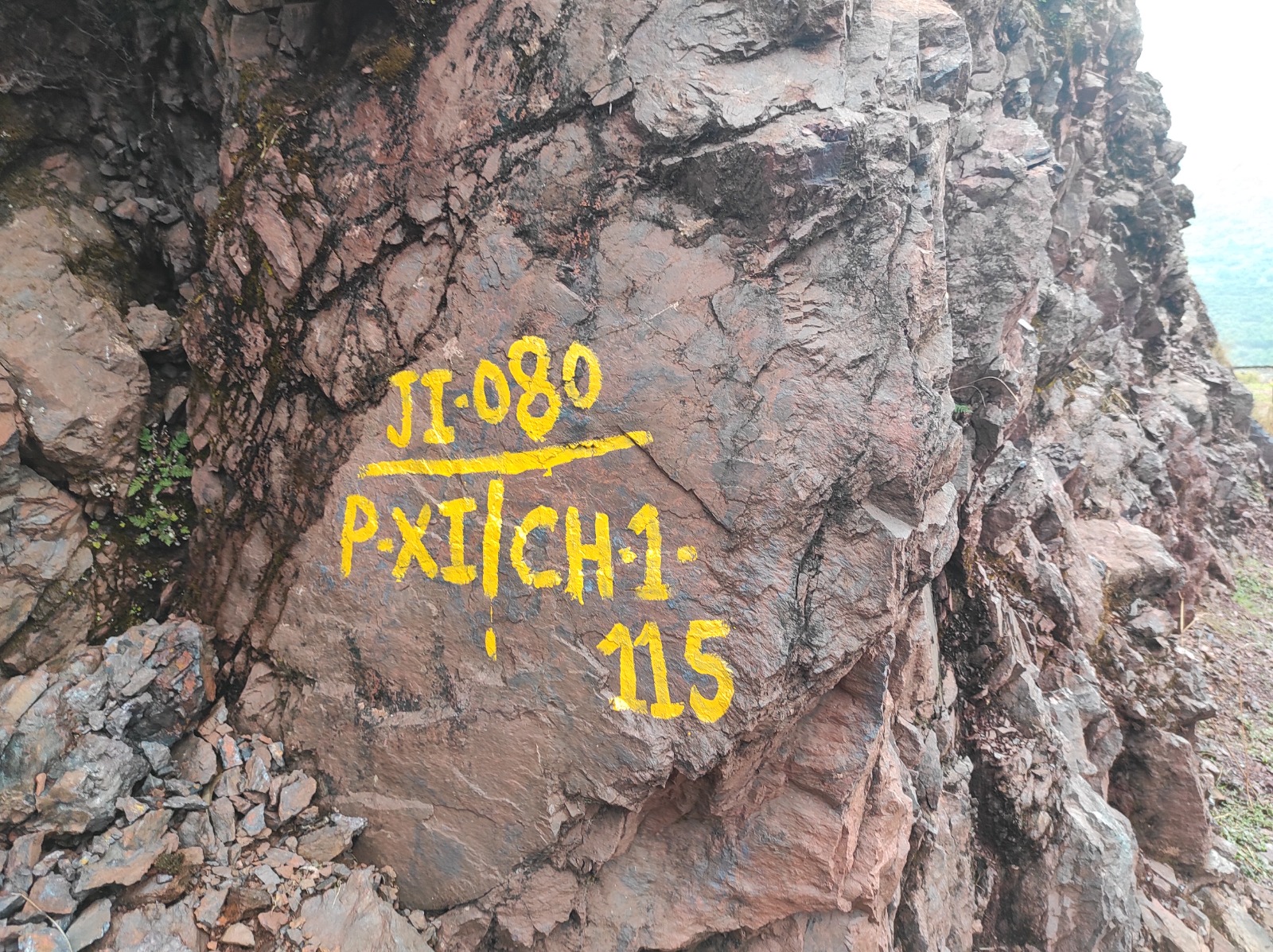

The story of the iron mine discovery in Jhumlabang is interesting. Geologists Saunak Bhandari and Basant Adhikari of the Department went to Rukum in May 2023 to search for a copper mine based on prior information. “We had read somewhere that copper is extracted in Sherabang and Jhumlabang, both in Bhume Rural Municipality. A good quantity of copper was also found in Sherabang,” Adhikari says. “On our way to Jhumlabang, we got lost and reached a place different from the copper mine. When we reached there, a sign of an iron mine appeared.”

A road had just been constructed at that spot. It was during that process that the evidence and proof of iron were seen. “Iron ore was visible outside. We also had a portable X-ray fluorescence (XRF) machine. Testing it showed that the iron content in the ore was 46 to 50 percent. That fact excited us,” Adhikari says.

After they returned from the field study, discussions were held about the possibility of an iron mine. The department deployed a team of experts in December 2023 for further study. The team spent two months conducting a topological survey, geological mapping, and channel sampling. 1,100 samples were collected and tested in a laboratory. That test showed that the ore contained an average of 45 percent iron (Fe). At least 30 percent iron is required in the ore to run a mine.

A local-level copper mine was already operational in Jhumlabang. In that village of a hundred households, the Magar community used to excavate copper in the past. The Bishwakarma community used to process it to make various materials. The Newar community used to sell those goods. “Initially, the Jhumlabang settlement was built for the copper mine. However, now with the operation of a large iron mine, that village will have to be relocated,” says Senior Divisional Geologist Pokharel of the Department.

Iron ore mining area in Jhumlabang, Bhume rural municipality. Photo Courtesy: Department of Mines and Geology

Twice as big as Dhaubadi

The place where the Jhumlabang iron mine was found is located 7 kilometers north of the Mid-Hill Highway. Jhumlabang is 165 kilometers north of Ghorahi, Dang, and 240 kilometers west of Pokhara. The mine located there is twice as large as the Dhaubadi iron mine discovered in Purbi Nawalparasi in around 2010. Dhaubadi has 99 million metric tons of ore. The ore there contains 35 percent iron. The Department of Mines established Dhaubadi Iron Company Limited in 2019 and started work. No solid progress has been seen there.

Processing one metric ton of ore from Dhaubadi yields 350 kilograms of iron. In Jhumlabang, 450 kilograms will be yielded. To extract iron from ore, the iron quantity must be 60 percent or higher. The mine found in Jhumlabang must be brought up to 60 percent through the process of refinement. Karmacharya of Elevate Mines and Minerals says, “In India, ore with 55-60 percent iron is directly put into the furnace and produced. In China, iron is produced from ore with only 30-35 percent. The Chinese technology may be more useful to us than the Indian.”

The mines in Jhumlabang and Dhaubadi are of the hematite type, which is an iron oxide mineral. The mine in Phulchoki, Lalitpur, is also hematite. The one in Those, Ramechhap, is magnetite, an iron oxide mineral that is highly magnetic. Hematite contains two parts iron and three parts oxygen. Magnetite contains three parts iron and four parts oxygen. Hematite is easier to refine, while magnetite is difficult.

The Jhumlabang mine is not spread over a large area. The ore is highly concentrated in a single location. There is a layer of ore up to 300 meters deep. Whereas in Dhaubadi, such a layer is limited to 20-25 meters. Therefore, even though the mine in Dhaubadi is spread over a large area, the quantity of ore is less than in Jhumlabang. “It looks as if someone brought and piled up a large quantity of ore in Jhumlabang from outside. Therefore, mine is the largest ever in Nepal,” says Senior Divisional Geologist Pokharel.

Mine area at Jhumlabang after marking by the Department of Mines and Geology. Photo Courtesy: Department of Mines and Geology

Seeking alternatives for raw material transport

Although Jhumlabang is suitable for a mine, it lacks infrastructure. Jhumlabang is in a different geographical situation than the Dhaubadi mine, which is close to roads and physical infrastructure. Dhaubadi is only 20 kilometers north of Kawasoti on the East-West Highway. Whereas, even though Jhumlabang is 7 kilometers north of the Mid-Hill Highway, it is not suitable for transporting the industry’s raw materials. It would require 100 to 150 Bigha of land to build an iron factory there. “It seems impossible to find a place with 150 Bigha of land in a hilly region,” says Karmacharya.

The goal is to increase ore excavation in Jhumlabang up to 12,000 metric tons. However, transporting even 4,000 metric tons to the factory requires 200 dump trucks. One dump truck carries 20 metric tons. The roads leading to Jhumlabang are not suitable for operating so many dump trucks. Pokharel of the Department says, “The roads leading there are winding. They are not suitable for transporting the raw materials produced by the mine. It seems cheaper and more suitable to transport the ore via water pipeline rather than by road.”

If the cost of transporting raw material is low, the price of iron will also be low. The mine operator claims that this would allow them to compete with Indian production. “We are looking for a less expensive way to transport. We will adopt whichever option is suitable among pipeline, monorail, and ropeway,” states Karmacharya. According to him, these issues are still in the study phase and may take two to three years to reach a final conclusion.

The special feasibility study report has shown that 1,500 tons of iron can be produced daily from Dhaubadi. The company estimates that if iron is produced in the country, imports can be reduced by one-fourth. Additionally, there is a projection that 2,500 to 3,000 direct jobs will be created there.

Janak Bahadur Chand, Chief Executive Officer of Dhaubadi Iron Company, says that work will be done to show that there is a possibility of operating iron mines in Nepal. “The operation of iron mines and factories is a new subject for Nepal. We are moving forward by paying attention to all issues,” Chand says. “If the cement industries had not been opened in Udaipur and Hetauda by the government level yesterday, the private sector would not have dared to invest this much. There would also be a shortage of manpower, and we would not be self-reliant in cement.”

The mine is being prepared to be operated with 55 percent investment from the government and 45 percent from the private sector. The estimated cost of running the factory is Rs 51 billion. The company has tested samples collected from drilling at various times in a Chinese laboratory. This has shown that the iron mine can be commercially viable.

Iron-rich rock/ore found within the Jhumlabang mine area. Photo Courtesy: Department of Mines and Geology

Priority on electricity usage

In operating the Jhumlabang mine, there is an attempt to use electricity as an alternative to coal. “If we can arrange for slightly cheaper electricity, production will also be cheaper. We are also looking at new technologies that use electricity,” says Karmacharya.

Factories that use coal as an energy source are among the biggest polluters globally. The role of such factories in global pollution is 5-6 percent. “We are trying to switch to an electrical system as much as possible to avoid pollution. We are talking to foreign consultants for that,” he says.

The company has estimated that the project will involve an investment of more than Rs 100 billion. Karmacharya says, “It will be the largest industry in Nepal. If Nepali capacity proves insufficient, there is a discussion about whether to collaborate with other countries once we reach the mining stage.”

The facts that emerge after drilling and the environmental assessment will further clarify the feasibility of operating the mine. The operation of the Jhumlabang mine appears to be important for Nepal’s aspiration to become self-reliant in iron production. This will be determined by infrastructure, transportation, and environmental impact.